Technology for Turning Residues into New Useful Products

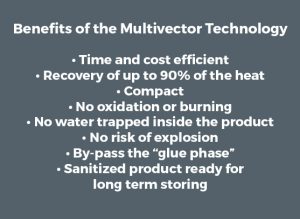

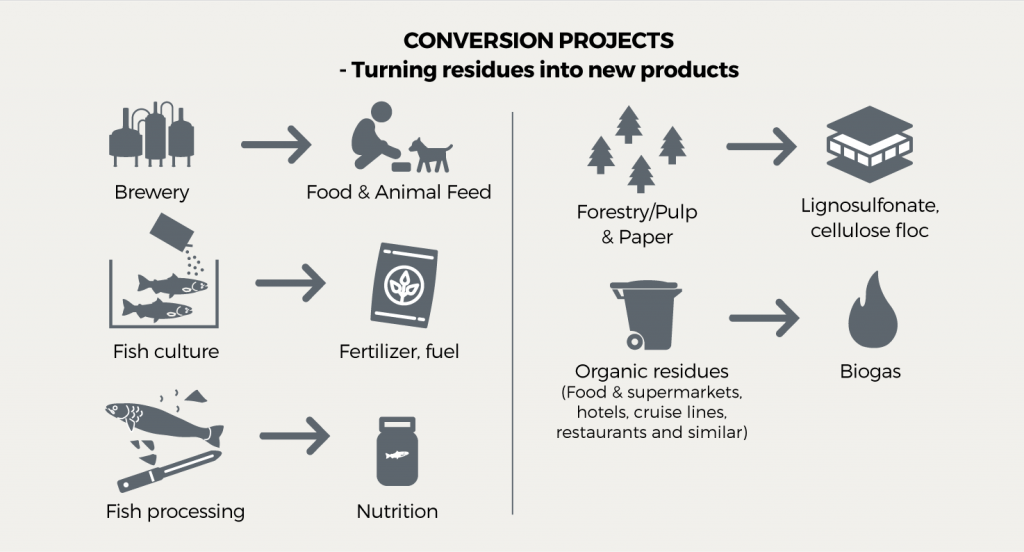

CellMark’s Technology team will be at the Drinctec exhibit to present to brewers a revolutionary drying technology for organic materials and residuals together with Multivector, the Norwegian company behind this technology. The team provides technical solutions to global corporations as well as small local businesses with a high focus on sustainability, time and energy efficiency. The Multivector technology free up and improve capabilities, reduces volume, lower transportation cost and simplifies handling of waste.

In fact, it turns waste into a useful transportable commodity while making your core business more cost efficient. And if that’s not enough, this technology is applicable for almost all areas of biomass processing, not only for brewers.

The Multivector can be designed for both industrial and small scale mixing and drying processes, as needed. The technology is based on mechanical fluidization where rotors with patented shovels secure a good mix and that a huge amount of surface area is exposed for drying. Superheated steam, generated from the moist of the input, is used in the drying process.

Come and meet us, at the Drinktec 2017 exhibition in

Munich Sep 11-15, to experience our solutions in turning

Brewer’s grain into consumable food and animal feed.

We will be at hall B2 stand 150 and are looking forward to meet you!

Contact our Technology team to set up a meeting:

Jonathan Östergren-Booj at +46 705804595

Martin Skoger at +46 705451591